Moldex3D

Key to Your Core Competitiveness

Cost Saving for Your Business

Moldex3D’s leading true-3D molding simulation can be applied in a wide range of plastic molding processes. It predicts potential manufacturing defects, validates part/mold design, lowers mold development costs, evaluates manufacturability, shortens time-to-market, and greatly increases business value.

- Shorten cycle time and time-to market

- Reduce number of mold trials and manufacturing costs

- Increase revenue and ROI

- Minimize product defects and extend mold life

Optimize Part/Mold Design Process

Intuitive User Interface to Streamline Simulation Workflows

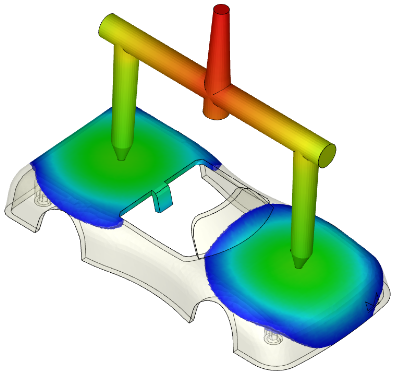

Validate and Optimize with Plastics Injection Molding Simulation

Moldex3D is the world-leading CAE product for the plastic injection molding industry. With the best-in-class analysis technology, Moldex3D can help you carry out in-depth simulation of the most extensive range of injection molding processes and optimize product designs and manufacturability.

Issue Diagnosis for Your Product Predict upfront most of the common manufacturing problems, such as short shot, flow imbalance, air trap, or hesitation. It greatly improves part quality, structure, and appearance.

Basic analysis options

Flow

- Predict melt front and flow pattern

- Optimize gating locations and design.

- Diagnose common manufacturing issues (weld line, flow imbalance, air trap, short shot, etc.).

Pack

- Evaluate gate-freeze time.

- Avoid sink mark or flash.

- Optimize packing profile.

Cool

- Improve cooling efficiency.

- Reduce cycle time.

- Predict hot spots.

Warp

- Predict final part shape.

- Identify warpage causes.

- Perform nonlinear analysis for large deformation.

Multiple-Material

Product and Design

Multi-Component Molding (MCM)

- Simulate Insert and Sequential Shot Molding.

- Detect potential re-melt issue.

- Predict warpage and cooling with different materials.

- Evaluate the impact by thermal and fiber condition in insert component from another shot.

Advancing Material Simulation

Fiber

- Visualize fiber orientation, length, and concentration inside fiber-reinforced plastics.

- Evaluate the filler effect to mechanical properties and final shrinkage.

- Optimize process conditions to enhance the part strength.

- Support short, long, flat fiber, and flake orientation simulation.

FEA/Micromechanics Interface

- Export fiber orientation, material anisotropy, residual stresses, weldline strength and molding pressure to structural software.

- Validate the structural performance of products and mold sustainability.

Moldex3D Digimat-MS

- Bridge manufacturing process and FEA analysis.

- Predict the mechanical behaviors with nonlinear material modeling technology for reinforced plastic.

- Define material properties and criteria of failure properties for reinforced plastic.

- Support automatic reverse engineering for material model generation based on experiment data.

System Requirements