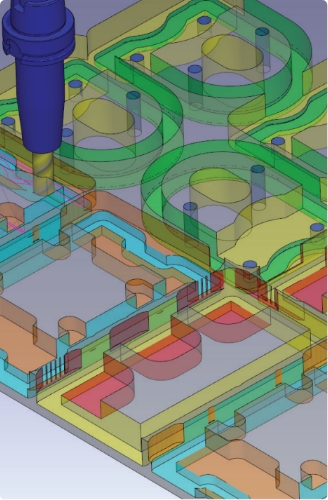

Milling

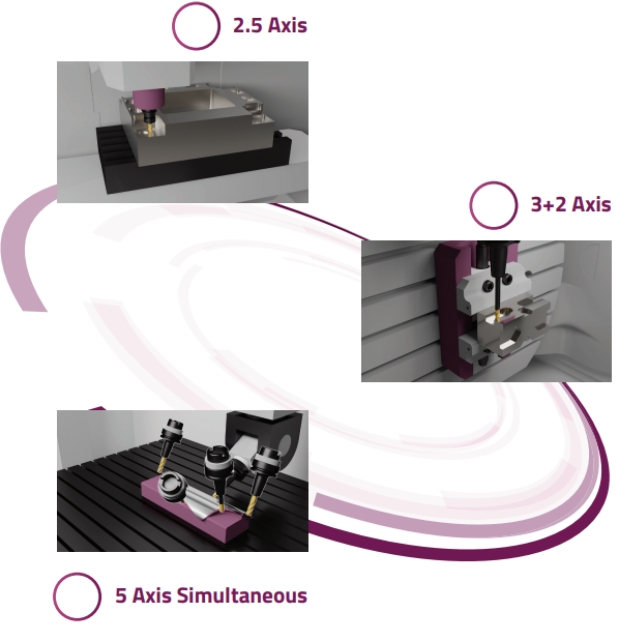

GO2cam designed an operating software of CNC machine-tools, supporting all dimensions and axis: 2D or 3D geometry, from 2.5 axis to 5 simultaneous axis. All type of machine, over 5 axis are supported.

GO2cam software suite is adapted for all kind of materials, from soft to hard. Huge online libraries of tools and cutting conditions are available

MILLING CAD POINTS

- Compatibility & associativity with CAD files (SolidWorks, Siemens PLM, CatiaV5, 3DExperience, Creo),

- Parametric CAD kernel,

- Smart dimensioning based on average tolerance,

- Smart features: holes, pockets

MILLING CAM POINTS

- Milling 2.5x – 3x – 5x simultaneous,

- Save expertise (operation list, tools),

- Stock management to avoid air cutting,

- Fixture management automatization to avoid collision,

- Estimation of production cost price (material, tools, machining time…),

- Machine-Tool Environment (MTE) simulation

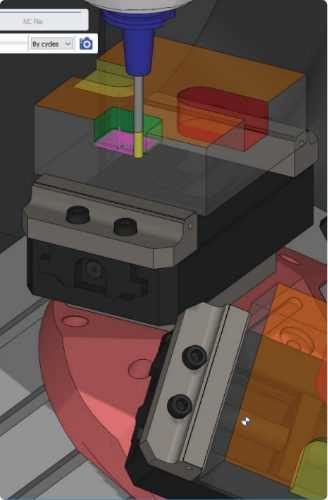

Multiple Part Machining

Solution for large scale production which offers a simultaneous optimization of a toolpaths, management of tool changes, support rotation and machine kinematics and other features.

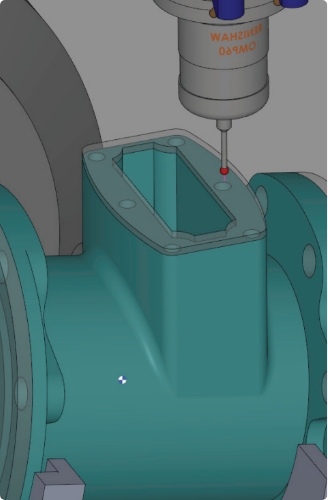

Probing

Scan QR code to find out more about our modules Other available add-ons : High Performance Machining (millyuGO), Boring head, Hole Machining Feature (HMF), Gun drilling, 5 axis expert, User Workshop documents.

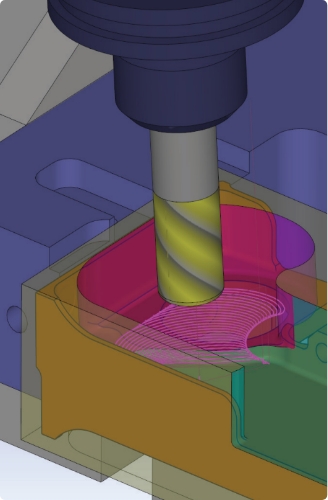

High-speed machining toolpath for high material removal rate production issues. This module calculates all the toolpath in order to optimize forces exerted on tool and spindle, from the first roughing cycle to the finishing.

Module operating in two probing stages (raw material, then origins). After finishing, a final probing cycle is launched to check the obtained dimensions. With predefined strategies and automatic calculations, there is no more need for a 3D measuring machine.

Nesting

Optimization of the positioning of multiple parts milled in the same raw material plate. Produce the highest number of parts and save raw materials.

millyuGO®

High-speed machining toolpath for high material removal rate production issues. This module calculates all the toolpath in order to optimize forces exerted on tool and spindle, from the first roughing cycle to the finishing.